The Difference Between Industry 4.0 and IoT

Here’s the skinny on Industry 4.0 and the Internet of Things and what smart manufacturers are doing to leverage the data they both produce.

Two of the hottest buzzwords in real world technology are Industry 4.0 and the Internet of Things (IoT). Sometimes they are used almost interchangeably, but while there is an overlap, they are not synonymous. I’ve written a bit about them in the past, but here’s the skinny on what they are, how they are related and what smart manufacturers are doing to leverage the data they both produce.

Only 20% of consumers understand the term Internet of Things yet nearly 70% own an IoT device

–Metova Survey

What Is the Internet of Things?

The Internet of Things involves adding digital sensors and networking technologies to the devices and systems that we use every day in the analog world. Some of the most well-known consumer examples are Nest and Ecobee smart thermostats and Amazon’s Alexa-powered devices including the Echo smart speaker. Smart thermostats have sensors in multiple rooms, and connect to your phone and the Internet to allow you extended control over the temperature. They can also be connected to algorithms to control the temperature when you’re not home or based on weather patterns. They can even “detect” when you leave.

By 2020, 30% of our interactions with technology will be through “conversations” with smart machines.

– Gartner

The Internet of Things extends well into commercial and municipal uses as well and can include everything from building temperature control systems to sensor enabled trucks to digital manufacturing control systems. Intel has a great explainer video on the Internet of Things that covers additional uses.

What Is Industry 4.0?

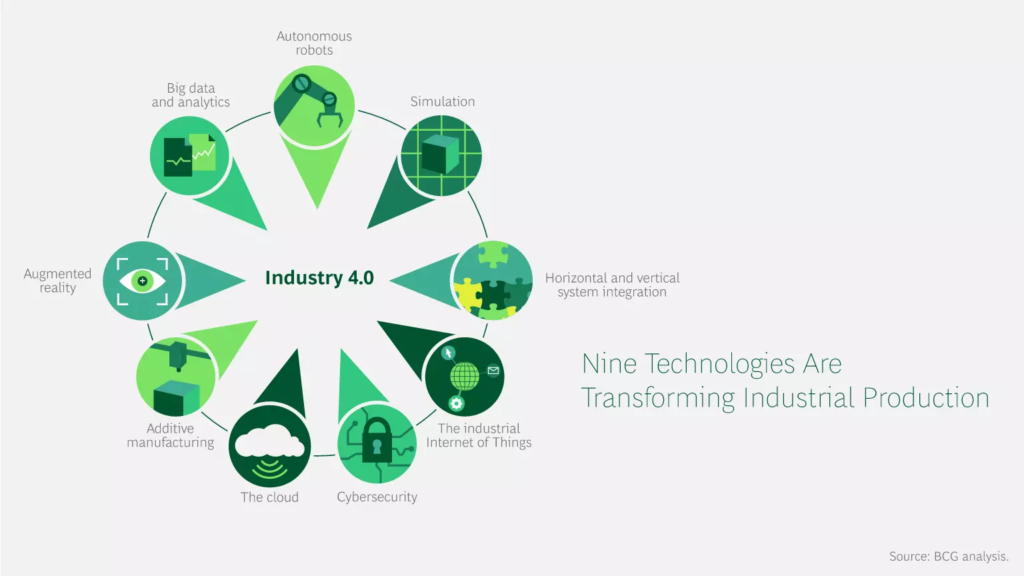

Industry 4.0 refers to the use of automation and data exchange in manufacturing. According to the Boston Consulting Group there are nine principal technologies that make up Industry 4.0: Autonomous Robots, Simulation, Horizontal and Vertical System Integration, the Industrial Internet of Things, Cybersecurity, The Cloud, Additive Manufacturing, Data and Analytics, and Augmented Reality. These technologies are used to create a “smart factory” where machines, systems, and humans communicate with each other in order to coordinate and monitor progress along the assembly line. Networked devices provide sensor data and are digitally controlled.

The net effect is the ability to rapidly design, modify, create, and customize things in the real world, while lowering costs and reacting to changes in consumer preferences, demand, the supply chain, and technology. So how are Industry 4.0 and IOT related exactly?

Industry 4.0 uses an Internet of Things, or at least an Intranet of Things, in order to perform digital manufacturing. All devices, robots, simulations, and tools have sensors and provide data.

Additionally, no manufacturer is an island as nearly every manufacturer has a supply chain which in turn has its own tools, and its own data, processes, and network. Bringing each of these networks together into a bigger Internet of Things promises to allow the entire supply chain to react more seamlessly to the market. This networked information sharing will help address long standard manufacturing problems like the Bullwhip Effect or tracing quality issues down a supply chain.

What Challenges Do the Internet of Things and Industry 4.0 Pose for Manufacturers?

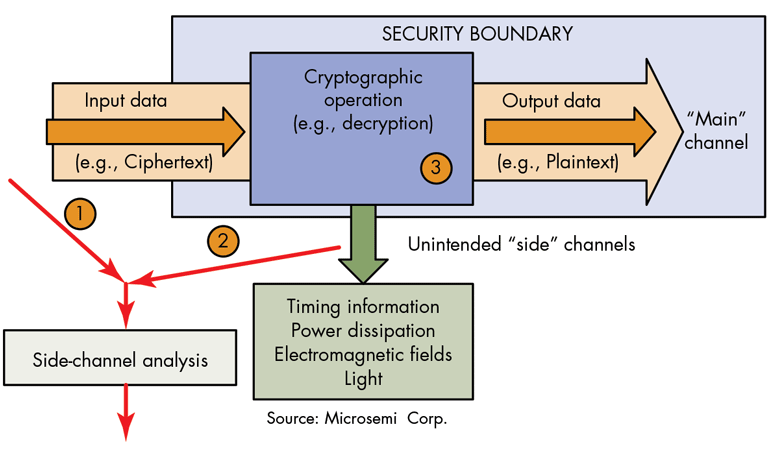

Given that both Industry 4.0 and IoT demand linking together previously independent devices and systems, it isn’t surprising that a chief shared concern is security. As the trend of using smart devices increases, it will be harder to track breeches and manage all of those devices (Khan/Turowski p6). Industry is moving quickly to address these security concerns, melding new technologies with standard IT security technologies like network security and encryption.

Another hurdle for both IoT and Industry 4.0 has been the lack of standards. Having a bunch of smart devices is great, but if they all record data in their own format and require their own protocol, integrating them into an automated factory will be cost prohibitive and difficult. Manufacturing giants like Bosch, the Eclipse Foundation, and others have been working on standard communication protocols and architectures like OPC UA, MQTT, and PPMP. These all aim to help smart devices, including those on the factory floor, communicate with each other and provide common data formats. But more data formats can mean more difficulty in creating one data model.

There are additional challenges for Industry 4.0 and IoT from talent development to IT integration as well as the mere immaturity of some of the technologies. As with any great transformation, there will be transitions that hybridize older methods and technologies with the new, along with risks and rewards.

A “horsecar” – a trolly on a track drawn by a horse. A hybrid technology in place contemporaneously with trolleys, early automobiles, and trains.

What Role Does Search Play in Industry 4.0 and IoT?

Industry 4.0 will generate enormous quantities of data. Gathering, analysing and processing such big data will generate new insights, support decision-making and create a competitive advantage.

–Deloitte

Search is the original Big Data technology and IoT and Industry 4.0 will create massive amounts of data. Being able to ingest that data quickly to find and analyze that data efficiently and effectively will be perhaps the greatest challenge and opportunity of Industry 4.0. In addition, providing appropriate information to humans in the process permeates many of the challenges of Industry 4.0. Whether it is a shortage of talent or organizing new talent, success will require presenting them with the relevant information they need, personalized to them and their task at hand.

Moreover, Industry 4.0 will produce a lot of stuff from digital twins to actual components. It will be essential to track, organize, understand, and find those components in context. In other words: if smart devices are the fingers, arms, and limbs, and the Internet is the nervous system, then search is the the brain behind Industry 4.0 that makes everything work together.

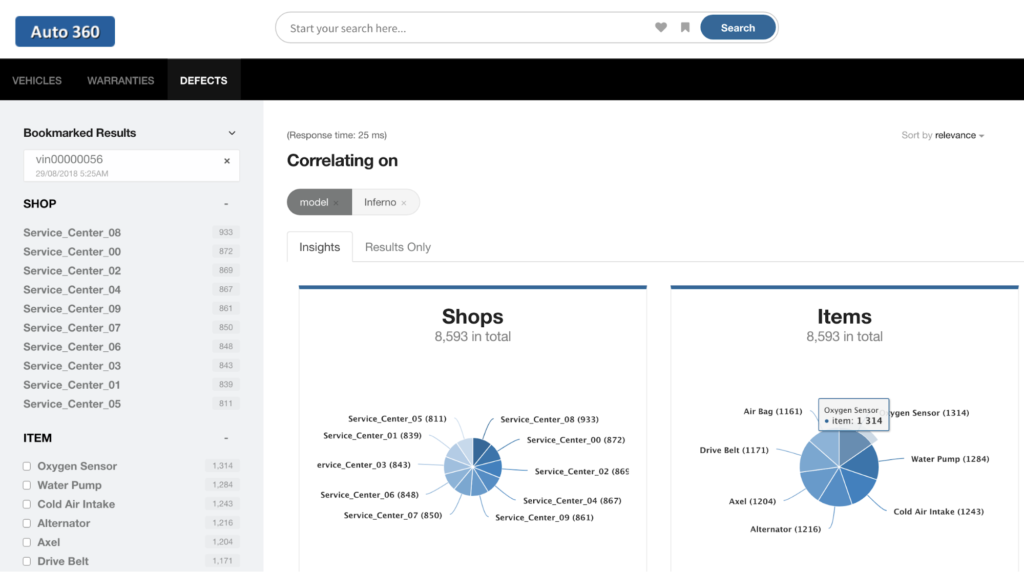

Two key examples of Industry 4.0 search include

- Product 360 – used to understand all of the components of a product and their fault data.

- Enterprise Search / Knowledge Management – used to ensure that each person from marketing to design to quality control can find the relevant information they need from procedures to specifications to models.

Learn more:

- Check out the EBook: Enterprise Search Buyer’s Guide.

- Sign up for our our Product 360 Webinar.

- Contact us, we’d love to hear from you.

- See how IoT impacts healthcare — Patient Outcomes Improve With IoT and Machine Learning

LEARN MORE

Contact us today to learn how Lucidworks can help your team create powerful search and discovery applications for your customers and employees.