Gen AI Implementation Costs Skyrocket: Navigating the AI Landscape in Manufacturing

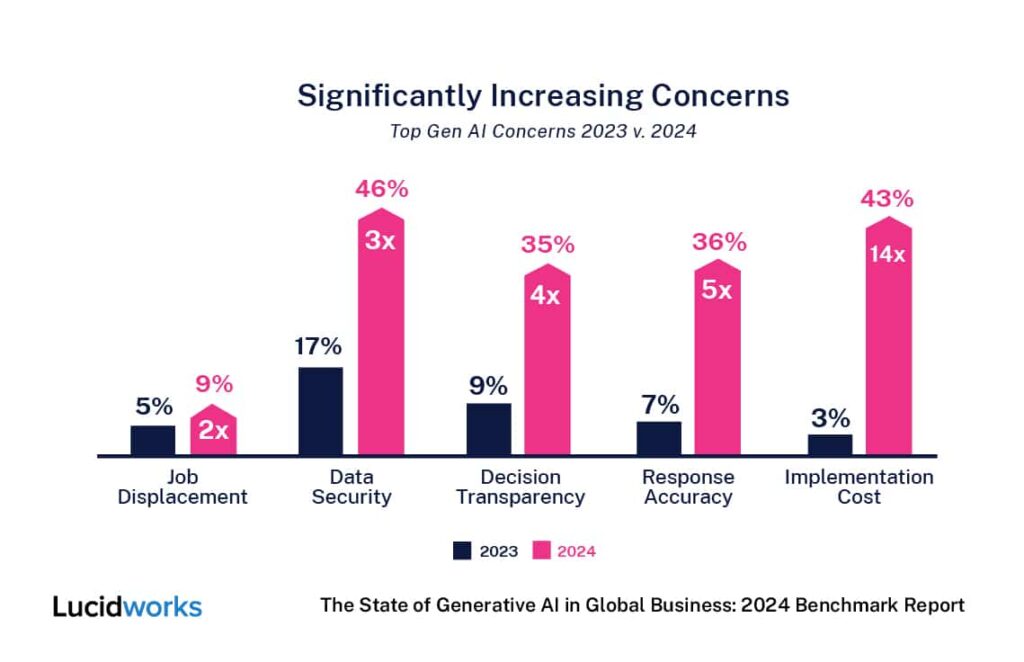

AI implementation costs have skyrocketed 14-fold in the last year! This shocking finding from Lucidworks’ 2024 Gen AI Benchmark Report highlights the challenges and opportunities facing manufacturers in the rapidly evolving world of AI. While nearly half of manufacturers already report cost benefits from their AI initiatives, this dramatic increase in implementation costs demands a strategic and measured approach to adoption.

This blog explains the key findings and insights from the 2024 Manufacturing Edition: Generative AI Benchmark Report, shedding light on the surprising trends, challenges, and successes that are shaping the future of AI in manufacturing.

The Soaring Cost of AI Implementation

One of the most startling findings in the report was the 14-fold increase in AI implementation costs over the last year. To put this in perspective, average implementation costs can now reach $190,000 (or more) for a bespoke generative AI solution. This dramatic surge has surprised many and forced a re-evaluation of AI investment strategies.

This increase in concerns surrounding implementation costs underscores the complexity of deploying generative AI at scale. Integrating AI into existing systems, ensuring compatibility, and training staff require substantial investment. Moreover, the need for robust data infrastructure and cybersecurity measures adds to the expense. Adding to this challenge are growing concerns around the accuracy of AI, particularly generative AI models, which necessitate increased investment in testing, validation, and potential rework to ensure reliable outputs.

Cautious Optimism on AI Spending

A notable trend from the report is the significant decrease in interest for increased AI spending year-over-year. In 2023, a staggering 93% of manufacturers planned to increase their AI spending. This year, that number has plummeted to less than 60%.

This shift is largely attributed to the rising implementation costs and a move towards more deliberate planning and longer-term investments. This suggests a shift towards more strategic and measured approaches to AI adoption, where manufacturers are prioritizing long-term value over rapid expansion.

Despite the overall decrease, a significant portion of organizations remain committed to investing in AI. 36% of companies are keeping their spending flat, 63% are still planning to increase their budgets, while only 2% are decreasing spending. This cautious optimism reflects a growing understanding of the complexities of AI adoption.

Manufacturers Forge Ahead

Manufacturers are emerging as leaders in AI adoption, with nearly half of manufacturers already reporting cost benefits from their AI initiatives compared to other industries. This success can be attributed to their focus on operational efficiency and leveraging traditional machine learning tools to optimize key processes.

Manufacturers have managed to keep deployment delays to a minimum – only 17% experience delays, compared to 22% in the technology sector and 24% in healthcare. This efficiency stems from well-established processes and a readiness to integrate AI solutions into existing workflows.

Beyond this, manufacturers are heavily investing in operational excellence (OpEx) initiatives, leveraging AI to:

- Monitor invoice elements and purchase price variance

- Optimize supply chains

- Predict and manage inventory levels

- Improve energy efficiency

- Streamline production processes

These applications help streamline procurement, enhance cost management, and improve overall efficiency, contributing directly to the cost benefits manufacturers are reporting.

Did you know?

Lucidworks clients are more than 2.5x more likely to successfully deploy generative AI initiatives than their peers.

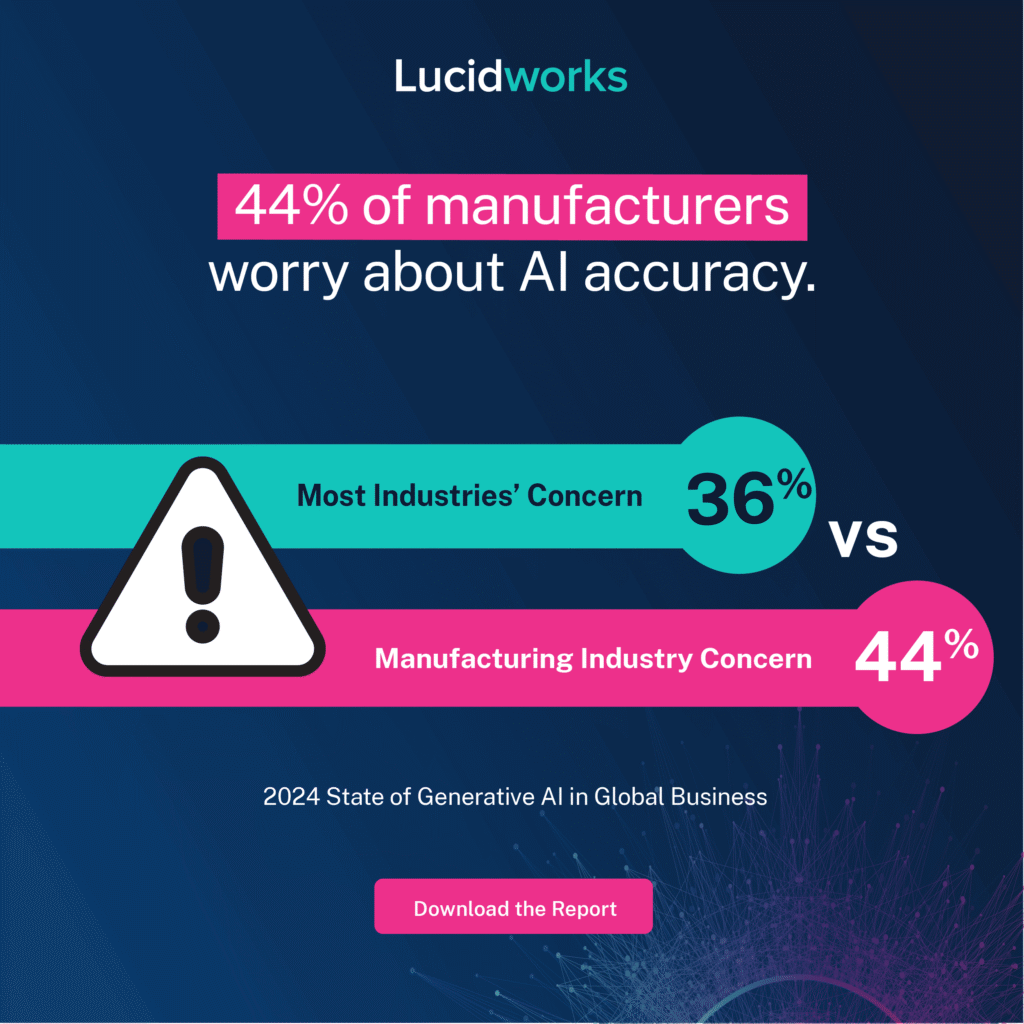

Accuracy is Paramount

Manufacturers place a high premium on response accuracy, recognizing the critical role it plays in meeting the precise needs of B2B buyers. This need for precision is driven by:

- Dynamic Pricing: Manufacturers often have complex pricing structures. Accurate responses, especially those generated by AI systems, are essential to ensure buyers receive the correct pricing information.

- Precise Part Requirements: Providing exact specifications in B2B commerce and distribution is crucial. Even a small error in an AI-generated product description or specification can lead to significant disruptions.

- Maintaining Trust: Consistent accuracy builds confidence among buyers, leading to long-term partnerships. Inaccuracies, on the other hand, can erode trust and damage relationships.

Addressing Cost and Security Concerns

While cost remains a concern for manufacturers, it is less pronounced compared to industries like retail. Similarly, security concerns are less acute than in sectors like finance and healthcare.

To manage costs, manufacturers can:

- Adopt phased implementation strategies

- Leverage cloud-based AI solutions

- Partner with AI vendors offering flexible pricing models

On the security front, manufacturers should:

- Implement robust cybersecurity measures, including encryption and regular audits

- Prioritize data security to ensure the accuracy of AI models

- Collaborate with cybersecurity experts

Lucidworks offers robust security features and flexible pricing models to help manufacturers confidently adopt AI. Schedule a demo to see how Lucidworks can transform your operations.

The Future of AI in Manufacturing

Despite the challenges, the future of generative AI in manufacturing looks bright. As language models (LLMs) become more specialized and cost-effective, we can expect to see wider adoption across the industry.

To stay ahead of the curve, manufacturers need to:

- Develop comprehensive AI strategies: Explore best practices for AI implementation, including phased approaches and pilot projects.

- Prioritize accuracy and risk mitigation: Invest in robust testing and validation processes to ensure the accuracy and reliability of AI systems.

- Embrace continuous learning and adaptation: Stay informed about the latest AI trends and developments to adapt strategies and maximize the potential of this transformative technology.

By understanding the current landscape and embracing a strategic approach, manufacturers can unlock the full potential of generative AI and drive innovation, efficiency, and growth. Download the manufacturing edition of our 2024 Gen AI Benchmark Report to learn more.