What Does Search Have to Do With Intelligent Machining?

Since the Industrial Revolution, manufacturing has seen a continuous march towards increasing levels of automation and the integration of machine…

Since the Industrial Revolution, manufacturing has seen a continuous march towards increasing levels of automation and the integration of machine intelligence. This progress in artificial intelligence and digital manufacturing has lead mainstream publications such as the Atlantic to ask: “If machines are capable of doing almost any work humans can do, what will humans do?” Let’s talk about intelligent machining.

And the answer, of course, is: “everything else.” This includes among other things: design and ideation as well as problem-solving defects and faults. In order to do “everything else,” the humans need information about what, how, and where as well as information about the machines they’re working with and the things they’re creating. Finding any and all of that—in time and with the right context—is the very nature of search.

The Digital Thread

Manufacturing is by definition a creative endeavour. When you include the design element and consumer demand elements, it is on par with art or music. Instead of a symphony though, manufacturers make things that people use every day.

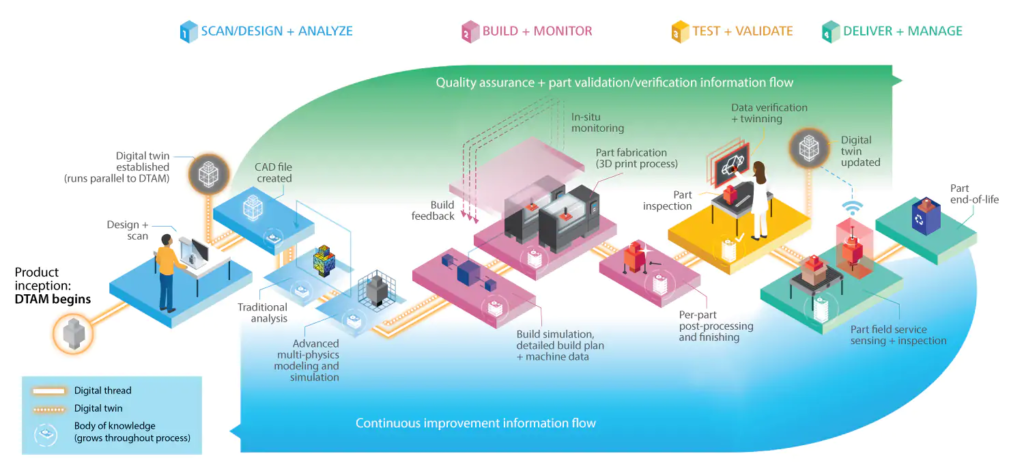

Today’s smart factories operate along a digital thread with a process that, roughly speaking, looks like this:

- A designer creates a “digital twin” in CAD software.

- The design is then simulated and stress tested. For instance, UnderArmor simulates how fabrics will hang on a human model.

- A “build plan” is created and simulated. This basically details what has to be done to realize the design.

- The design is then fabricated using a series of tools, robots, and processes.

- Finally the creation is verified, possibly modified, and rescanned.

(Find out more on Deloitte’s excellent summary “3D opportunity and the digital thread.”)

So what does this have to do with search? Let’s look more closely at the process.

Credit: Deloitte

Intelligent Machining

Traditionally, tooled manufacturing involved an operator controlling a machine like a cutting device or an additive process and then making decisions based on analog or digital sensor readings. Automated manufacturing, or intelligent machining, requires a finer degree of data and computer algorithms. These are essentially mathematical expressions of operator activities1.

The sensors in all of the intelligent machines help form a series of closed loop systems and an overall closed-loop manufacturing process. Different machines perform different manufacturing tasks from cutting to 3d-printing out components. Sensors and an overall build plan drive each machine and the overall process. This includes detecting faults but also control functions, like positioning a component about to be pressed, drilled or cut. At each step, quality variations can be detected, processes can be adjusted and better designs can be made.

All of this involves the creation of data. That data has to be found to be used — and finding things requires intelligent search.

Manufacturing as an Enterprise

Manufacturers do not have the luxury of just making things. Manufacturers must also market things, sell them to customers, and manage relationships with suppliers and usually other manufacturers.

Watch our previously recorded “AI for Omnichannel Retailers” in order to understand how recommendations can be used to close deals.

Next, if there could be one axiom for all of manufacturing history it might be that nothing is perfect and all imperfections are defects. Each component from the supply chain or created locally will likely one day undergo modification or revision. Some of the finished products will come back from the customer as returns. To implement any kind of necessary quality control, it is essential that those products be linked with their components and those components with their revision numbers and those revision numbers with their digital twin and the plan and processes which created them.

Sign up for our “Product 360 Webinar” to learn more about how manufacturers manage this data.

Search in Manufacturing

Notice that there are still people in the digital thread diagram? Those people consume data, they have questions, and need to understand procedures and events. This data has to be found and contextualized. With today’s volumes this necessitates “smart search” that uses AI to help personalize results.

Numeric data like sensor data and return data are coming together with textual data like component data and process and procedural descriptions in order to make better decisions and implement better more predictive quality control measures.

Search is the glue that keeps the digital thread together by making information accessible to both the people and the machines involved in the manufacturing process. If they can’t find it, they can’t do it.